DBC

Tech. Info 03

Colloidal Silica

Particle & Surface

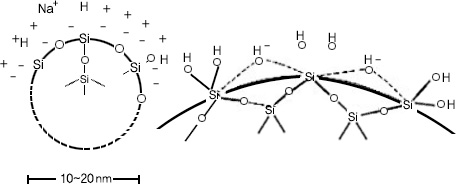

- SS-SOL is colloidal silica consisting of spherical particles of silicon dioxide (SiO2) dispersed in water

- Silica surface is charged by hydroxyl ions formed by loss of protons from water molecules in the spaces between the oxygen atoms of the structures.

- According to this electric charge of particles, it has formed gelation, aggregation and colloid. If the particles are smaller than 7nm in diameter the sol is almost as clear as water.

- From 10nm to 30nm there is a characteristic opalescence or transparency when seen it. And above about 50nm the appearance is white and milky.

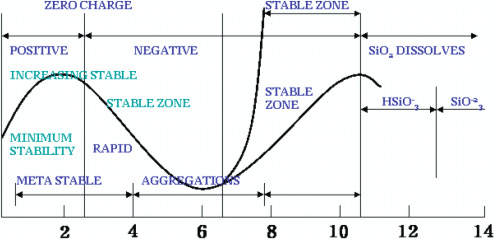

Effect of pH

Use of SS-SOL

-

Increasing the coefficient of friction

Increasing the friction of solid surfaces. For example, railway tracks, waxed floors, and textile fibers.

-

Adhesion, Film

Forming strong and rigid solid surface.

-

Stiffening

Because it can be produced rigid gel by sintering, it is used for stiffening powder.

-

Increasing cohesion by Gelation

It can increase cohesion, formed uniform gel by gelation. And it can be dispersed. Therefore it can be stabilized supporter

-

Increasing hydrophilicity & prevention electrification

Hydrophilicity can be increased by Si-OH, and electrification can be prevented.

-

Increasing activity

Because of lower ion concentration and higher silica concentration, when liquid is mixed reaction is uniform. And activity rate is faster.

-

Lager surface

After dried colloidal silica, it can be got silica gel large that has surface area and uniform pore.

-

Impregnant & Filler

It is used for filler of porous substance. And it is environmental harmony because of lower Na+ concentration.

Frictionizing Effets

-

Fibers

Colloidal silica is coated with a cationic quaternary ammonium type of surfactant before application to textiles for good frictionizing. Because of its fractionizing effects, silica is also an aid in processing wool. Slippage of glass fibers is prevented and colors are simultaneously bonded to the surface by the application of colored metal oxides along with colloidal silica and heating to bond the coating. To prevent knots in nylon fishnets from slipping, colloidal silica is mixed with and water applied to the knots.

-

Paper & Film

The surface of polyethylene terephthalate drafting film is improve with respect to reception of pencil and ink by applying colloidal silica along with an acid-soluble film-forming material.

제지공정

-

DIAZO 감광지

DIAZO 감광지에 SS-SOL을 첨가하여 용지의 표면을 평편하고 미끄럽게 하여 사진을 선명하게 하는 효과가 있습니다.

-

포장지 및 포장박스

SS-SOL을 포함한 경우 내구성과 방습성을 향상시킵니다.

-

셀로판 필름

SS-SOL과 글리세롤, Monostealate등의 왁스재료와 혼합한 수조에 필름을 담궈놓는 공정을 통하여 필름끼리 달라붙는 현상을 방지할 수 있습니다.

주조

-

정밀주조

SS-SOL은 세라믹 재료들과 강한 접착력을 가지고 있으므로 Ethyl silicate 대체품으로 사용하여 비용을 절감하고 작업환경의 개선효과 등이 가능합니다. 또한 소립자의 SS-SOL을 사용하는 경우 세라믹 재료의 강도를 개선할 수 있습니다.

-

착색

휘발성 착색재료의 주형 강도증강을 위해 기존에 사용된 메탄올 대신 SS- SOL을 사용한 경우 전성이 향상되고 주형의 강도가 증대되며 주조의 표면을 매끄럽게 처리할 수 있습니다.

-

CO2형 반응 촉진제

CO₂공정에서 규산소다와 탄산가스의 반응성이 낮으므로 그 공정에서 SS-SOL을 사용한 경우 반응속도가 올라가고, 작업성이 현저하게 증대됩니다.

세라믹 내화물

SS-SOL은 내열성 및 산에 견디는 성질과 응집력으로 인해 새로운 내화물질로 주목 받 고 있습니다. SS-SOL은 절연물질의 응집제로도 이용이 가능하며 탄소물에 이용될 때는 표면의 부식을 방지할 수 있습니다. 또한 철강제품 또는 내화물의 표면에 SS-SOL 단독 혹은 내화물질의 분말을 혼합하여 코팅을 하면 항열 항부식 효과를 가져옵니다.

Inorganic Binder, Stiffener

-

Molded Refractory Bodies

A mullite bonded refractory was made by mixing colloidal silica and basic aluminum chloride in proportions to form mullite and using this as a binder for mullite powder to form a mullite refractory body at 1300℃. Refractory bodies of silllimanite have been bonded with a mixture of colloidal silica and basic aluminum chloride acting as a binder for sillimanite powder, fired at 1300~1400℃. Cold-molded metal bodies with thermal conductivity can be made from metal powders using colloidal silica and latex as the binder.

-

Binders for Fibers

An inorganic binder for inorganic fibers is made by dispersing clay in colloidal silica, then acidifying to pH 3.5 and adding an aluminum salt such as aluminum formate. Fire-resistant reflective insulating material is made by binding fibrous potassium tianate with a mixture of latex and colloidal silica. Colloidal silica is used as binder in highly refractory aluminosilicate fibers. The stiffness and strength of organic fiber sheets or papers can also be improved with colloidal silica. In paperboard used for corrugating, stiffness is improved by impregnating with colloidal silica. From 1 to 5% colloidal silica in certain paper pulps gives improvement in strength, stiffness, stability, etc.

Modifying Adhesion

Colloidal silica can be applied to surfaces either to increase the adhesion to other materials, in effect by roughening the surface if the silica is adherent, or to decrease adhesion by holding otherwise “sticky” surface apart.

Making Catalysts, Gels, Asdorbents

The obvious advantage of stating with colloidal silica instead of sodium silicate are the ease of incorporation with other catalyst components, the minimum washing required to remove unwanted salts, and the wider, more than uniform pore structure obtained by forming the gel from relatively large, uniform colloidal particles.

The advantage of a catalyst base of colloidal silica spheres in a densely packed arrangement is that at elevated temperature, the mass cannot readily contract further and collapse or sinter, and the uniform pores between the uniformly packed uniform particles provide a constant surface area and high degree of catalytic activity.

The silica sol containing metal salts can be spay-dried or freeze-dried to give small spherical gel particles which can be further compacted as desired. Sol can be converted to a fine powder by dispersing the sol in a partly water-miscible organic solvent, gelation the silica, and distilling off the liquids.

배터리

납축전지에서 콜로이달 실리카는 황산과 반응하여 겔화되고, 겔화된 전해액은 누수방지효과 및 배터리 성능향상을 나타낸다.

Reinforcing Organic Polymers

The strengthening or reinforcing effects of colloidal silica in organic polymers, films, and fibers are so varied that they are not categorized. Silica has been incorporated into polyolefins, thermoplastic organic polymers, polyamides, and other types. Copolymerization of colloidal silica and soluble silicate polyester gives a strong water-impermeable mass. Aqueous sols are used in the rubber industry mainly for stiffening open-cell foamed rubber. The silica deposited on the walls of the pores apparently has frictionizing effects, making the foam less easily compressed and thus increasing load bearing capacity. A pickup of only 3% SiO₂ increase compression resistance by 90%

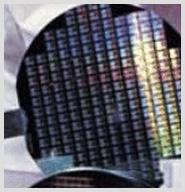

Polishing Agent for Silicon Wafers

In the electronics industry wafers cut from single crystals of silicon are polished to extreme smoothness using colloidal silica as a polishing medium at high pH.

Address: 278-11, Anha-ro, Hallim-myeon, Gimhae-si, Gyeongsangnam-do, Republic of Korea

Tel : 055-343-1266~7 ㅣ Fax : 055-343-1295 ㅣ E-mail : dongbang1266@wehago.com

055-343-1266~7

Fax . 055-343-1295E-mail . dongbang1266@wehago.com